0000921705 MTU fuel filter element

| Engine Type : | MTU1163, MTU595, MTU396, MTU538 |

| Part Number : | 0000921705 |

| Description : | FUEL FILTER ELEMENT |

| Unit Weight(KGM) : | 0.275 |

| HS Code : | 8421310000 |

| Condition : | New |

| Manufacturer : | Original |

Other Attributes:

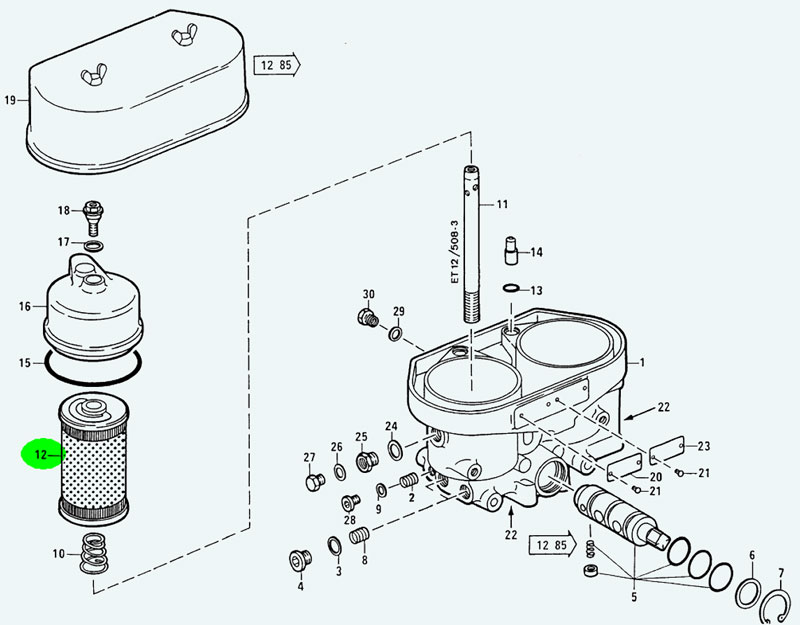

| C/N | Order No. | Description | Qty | U/M | Dimension |

| 000 | 0010920701 | FUEL FILTER | 001 | EA | |

| 01 | 8490920050 | HOUSING | 001 | EA | |

| 02 | 900421024000 | THREAD INSERT | 002 | EA | M 24X 1,5 X 12 |

| 03 | 007603024106 | SEALING RING | 002 | EA | A 24 X 29 |

| 04 | 000908024004 | PLUG | 002 | EA | M 24 X 1,5 |

| 06 | 8599970370 | SEALING RING | 003 | EA | 37.5 X 4 |

| 07 | 8490920060 | BUSHING | 002 | EA | |

| 08 | 8499970870 | SEALING RING | 004 | EA | |

| 11 | 000472050000 | SNAP RING | 001 | EA | 50 X 2 |

| 12 | 000N13311/1 | THREAD INSERT | 001 | EA | |

| 13 | 007603014106 | SEALING RING | 001 | EA | A 14 X 20 |

| 14 | 000908014001 | PLUG | 001 | EA | M 14 X 1,5 |

| 17 | 0000921705 | FUEL FILTER ELEMENT | 004 | EA | |

| 18 | 700294014005 | O-RING | 002 | EA | 14 X 2,5 |

| 20 | 8490920080 | VALVE | 002 | EA | |

| 21 | 8499970970 | GASKET | 001 | EA | |

| 22 | 700294125000 | O-RING | 002 | EA | 125 X 4 |

| 23 | 007603021100 | SEALING RING | 002 | EA | A 21 X 26 |

| 25 | 8490920070 | PROTECTIVE COVER | 001 | EA | |

| 28 | 006799008000 | LOCKWASHER | 002 | EA | 8 |

| 30 | 001476002000 | GROOVED PIN | 002 | EA | 2 X 4 |

| 31 | 003521017000 | PLUG KEY | 001 | EA | 17 |

| 32 | 001481003007 | SPRING PIN | 001 | EA | 3 X 30 – N |

| 33 | 900421010002 | THREAD INSERT | 004 | EA | A M10 X 20 |

| 36 | 007603024106 | SEALING RING | 002 | EA | A 24 X 29 |

| 38 | 007603018101 | SEALING RING | 001 | EA | A 18 X 22 |

| 39 | 007604018101 | PLUG | 001 | EA | A M 18 X 1,5 |

| 40 | 007604014102 | PLUG | 002 | EA | A M 14 X 1,5 |

0000921705 – MTU Filter Superseded Part and Effective Date:

| New Part Number | Superseded Part Number | Seq no | Hierarchie | Denomination (New Part Number) | Valid From Date |

| 0000921705 | 0000920505 | 0001 | Superseded | FUEL FILTER ELEMENT | |

| 0000921705 | 136L77702/1 | 0002 | Superseded | FUEL FILTER ELEMENT | 1993/4/1 |

| 0000921705 | 000N05220/1 | 0003 | Superseded | FUEL FILTER ELEMENT | 1993/5/1 |

| 0000921705 | 000N13033/1 | 0004 | Superseded | FUEL FILTER ELEMENT | 1993/6/1 |

| 0000921705 | 000N13227/1 | 0005 | Superseded | FUEL FILTER ELEMENT | 1993/7/1 |

| 0000921705 | 0004773415 | 0006 | Superseded | FUEL FILTER ELEMENT | 1993/8/1 |

| 0000921705 | 0000920905 | 0007 | Superseded | FUEL FILTER ELEMENT | 1993/9/1 |

| 0000921705 | 0000922905 | 0008 | Superseded | FUEL FILTER ELEMENT | 1993/10/1 |

| 0000921705 | 0000922805 | 0009 | Superseded | FUEL FILTER ELEMENT | 1993/11/1 |

| 0000921705 | 0000924905 | 0010 | Superseded | FUEL FILTER ELEMENT | 1993/12/1 |

| 0000921705 | 0000921705 | 0011 | New | FUEL FILTER ELEMENT | 1994/1/1 |

Introduction to MTU Filter (Part Number: 0000921705)

The MTU Filter (Part Number: 0000921705) is a fuel filter specifically designed for diesel engines by MTU Friedrichshafen GmbH (a subsidiary of Rolls-Royce Power Systems). Its primary function is to filter impurities and contaminants in fuel, ensuring efficient engine operation and extending the engine’s service life.

1. Core Functions and Technical Features

1.1 Precision Filtration

As an MTU factory-certified component, this filter adopts high-precision synthetic filter materials, which can effectively trap solid particles (such as metal shavings and dust) and moisture in fuel, with a filtration accuracy typically ranging from 5 to 10 microns. This feature is particularly critical for high-pressure common rail fuel systems, as it prevents wear and clogging of fuel injectors, ensuring the engine’s stability under high-load operating conditions.

1.2 Durability Design

The filter housing is made of corrosion-resistant steel, and its internal structure has undergone pressure resistance testing (withstand pressure up to 10-15 bar), making it suitable for harsh environments such as marine, railway, and industrial power generation. For example, in marine applications, the filter must withstand frequent vibrations and salt spray corrosion, while MTU’s sealing technology prevents leakage and maintains filtration efficiency.

1.3 Long Service Life and Maintenance Convenience

In line with the maintenance cycle of MTU engines, this filter is generally recommended to be replaced every 500-1000 operating hours or every 6-12 months. Some models support “spin-on type” quick replacement, allowing maintenance to be completed without special tools, reducing downtime.

2. Application Scenarios and Compatible Engine Models

2.1 Main Application Fields

1. Marine Power: Used in marine engines such as the MTU 20V1163TB93 to ensure fuel cleanliness during ocean voyages.

2. Industrial Power Generation: Compatible with MTU 4000 series generator sets to ensure the stability of continuous power supply.

3. Construction Machinery: Applicable to MTU 396 series engines in mining equipment and heavy-duty trucks.

2.2 Extended Compatibility

According to cross-reference information, 0000921705 may be compatible with the following components:

4. MTU 396 Series: Fuel filter for CPB 87 model engines.

5. MTU 2000/4000 Series: The fuel system design of some models matches this filter.

(Note: For specific compatibility, please refer to the engine nameplate or MTU official database.)

3. Quality Certification and After-Sales Service

3.1 Factory Certification Guarantee

This filter has passed MTU’s full-life cycle testing, including verification under extreme conditions such as high temperature, high pressure, and vibration, and complies with ISO 4548-12 (diesel filter performance testing standard). Using non-original components may lead to reduced engine performance or invalidation of the warranty.

3.2 Global Supply Chain Support

MTU provides spare parts support through its global logistics centers and authorized dealer network. In China, agents such as Tripoly International Group Limited can provide in-stock or pre-order services. For example, platforms like Jidianzhijia (Mechanical and Electrical Home) show that MTU diesel filters (e.g., 0010920301) are in stock, which indirectly reflects the supply status of similar components.

4. Maintenance Recommendations and Operational Precautions

4.1 Replacement Cycle

6. Routine maintenance: Replace every 500 operating hours or 6 months.

7. Harsh environments: In areas with high dust or sulfur-containing fuel, it is recommended to shorten the replacement cycle to 300 operating hours.

8. Tip: Using MTU original fuel additives together can further improve filtration efficiency and prevent wax deposition.

4.2 Installation Requirements

9. Ensure the sealing ring is undamaged during installation to avoid fuel leakage.

10. After replacement, manually drain the air from the filter to prevent difficulty in starting the engine.

11. It is recommended to use a torque wrench to tighten the filter housing to a standard torque of 25-30 N·m.

5. Purchase Channels and Technical Support

5.1 Official Channels

12. Visit the MTU official website (www mtu-online com) to find local dealers.

13. Contact China Customer Service (+86-21-5160-7890) to obtain technical documents or component drawings.

5.2 Third-Party Platforms

14. Industrial parts platforms such as Grainger and Alibaba International Station offer compatible products from alternative brands (e.g., Mann+Hummel, Fleetguard), but attention must be paid to compatibility.

6. Frequently Asked Questions (FAQs)

15. Q: Can filters from other brands be used as replacements?

A: It is recommended to use MTU original components first. Non-original products may cause engine failures due to insufficient filtration accuracy or structural differences. If alternative parts are selected, ensure they have passed ISO 4548 certification and are compatible with MTU engines.

16. Q: How to determine if the filter is clogged?

A: When the engine experiences difficulty in starting, reduced power, or a fuel pressure alarm, it may be a sign of filter clogging. A fuel pressure gauge can be used to detect the pressure difference between the inlet and outlet (normally less than 2 bar).

17. Q: Does this filter support fuel preheating?

A: Some MTU engines are equipped with a fuel preheating system and require a dedicated filter (e.g., models with heating elements). Whether 0000921705 has this function should be confirmed by referring to the technical manual or consulting the dealer.

Summary

The MTU Filter 0000921705 is a core component of the fuel system for MTU diesel engines. Its design balances filtration efficiency and durability, making it suitable for various industrial scenarios. It is recommended to purchase through authorized channels and strictly follow MTU’s maintenance specifications to ensure engine performance and reliability. For more detailed technical parameters or installation guidelines, please contact MTU technical support directly or access its official database.